Risk and Adverse Media Intelligence for Supply Chain and Manufacturing

Full visibility into supplier networks and production partners to keep sourcing resilient.

Why Supply Chains Need More Than Basic Screening

Global manufacturing and procurement teams manage thousands of suppliers across multiple tiers. Each supplier brings potential risk. Sanctions lists may reveal hidden restrictions, corporate registries may expose opaque ownership, and adverse media may uncover labor violations, environmental damage, or ESG controversies. Traditional processes often fail because lists are incomplete, data is scattered across tools, and manual reviews cannot keep up with the pace of sourcing.

Business Radar was built to address these challenges, unifieying sanctions, ownership, adverse media, and ESG risk intelligence in one place. It is designed for screening companies and related entities, ensuring a focus on corporate entities, subsidiaries, and parent groups that form global supply chains. With real-time monitoring and scalable integration, Business Radar makes it possible to run responsible sourcing programs without slowing operations.

210+

Risk Categories

90%

Reduction False Positives

135M+

Global Company Records

100+

Translated Languages

1,400+

Sanction Lists

How Business Radar Supports Supply Chain and Manufacturing

Supplier Onboarding

Procurement teams use Business Radar during onboarding to verify that potential suppliers are not connected to sanctioned entities, negative ESG controversies, or hidden ownership structures. This reduces onboarding delays and ensures new contracts start on solid ground.

Ongoing Portfolio Monitoring

Once suppliers are onboarded, Business Radar keeps entire portfolios under review. Teams can upload thousands of vendors and receive automatic updates whenever new risks emerge. Continuous monitoring ensures that ESG controversies or sanctions exposure are detected early rather than after they create disruptions.

ESG and Sustainability Oversight

Sustainability leaders use Business Radar to identify risks related to deforestation, land clearing, forced labor, or environmental penalties. Adverse media monitoring provides context beyond questionnaires or certifications, giving companies a reliable evidence base for responsible sourcing.

Audit and Compliance Readiness

Auditors and regulators increasingly require evidence of supply chain due diligence. Business Radar generates clear, exportable reports showing which suppliers were screened, what results were found, and how decisions were made. This creates a defensible record that protects both compliance and reputation.

Trusted by

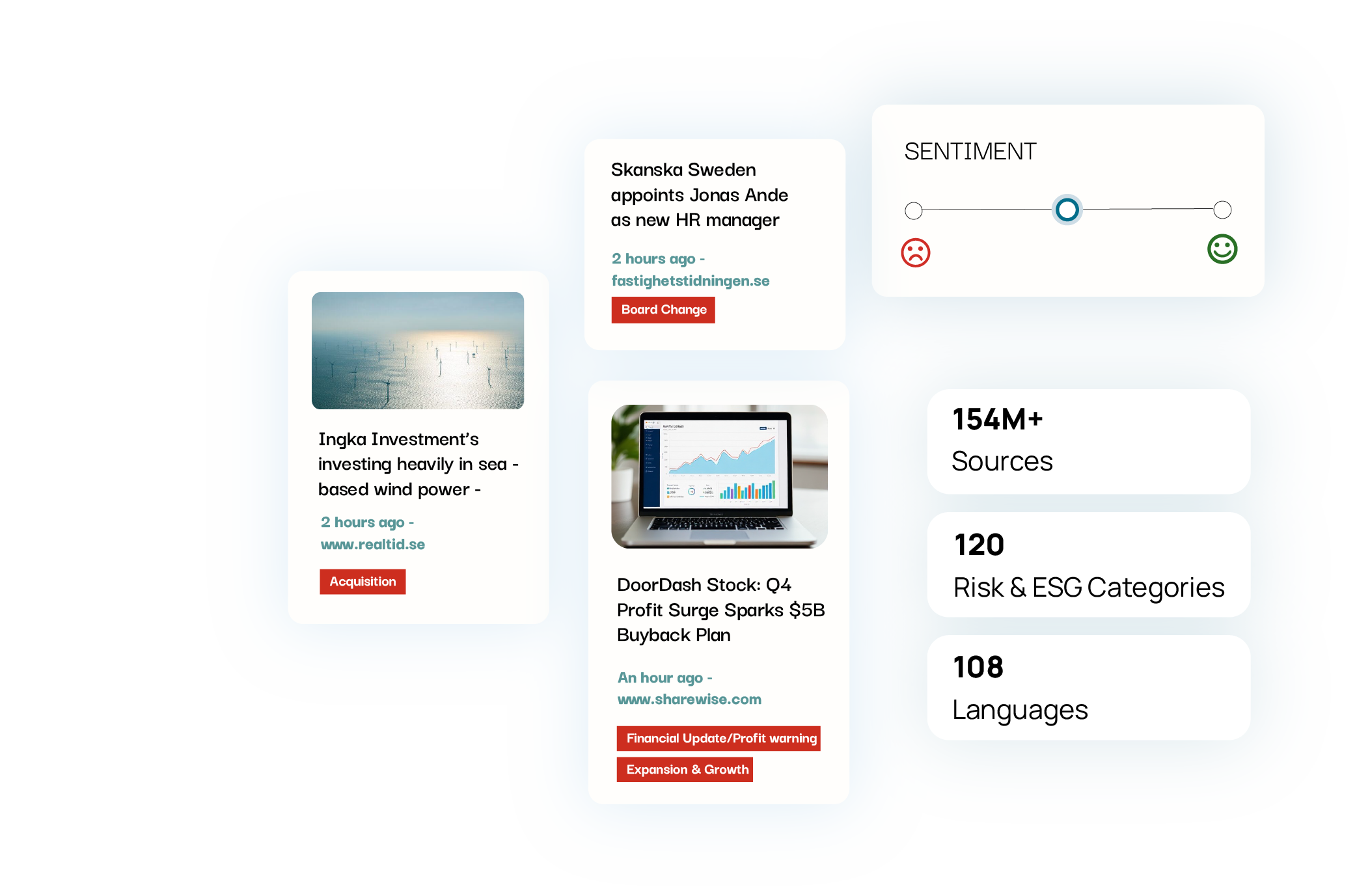

Adverse Media

Supply chain risks often surface in the news before they appear in any database. Business Radar monitors global and local sources in more than 100 languages to detect ESG issues, labor disputes, environmental violations, and regulatory penalties linked to your suppliers.

Procurement and sustainability teams use these insights to anticipate problems before they disrupt production or damage reputation. With real-time alerts, you know immediately when a supplier is mentioned in adverse media, so you can adjust sourcing or escalate reviews without delay.

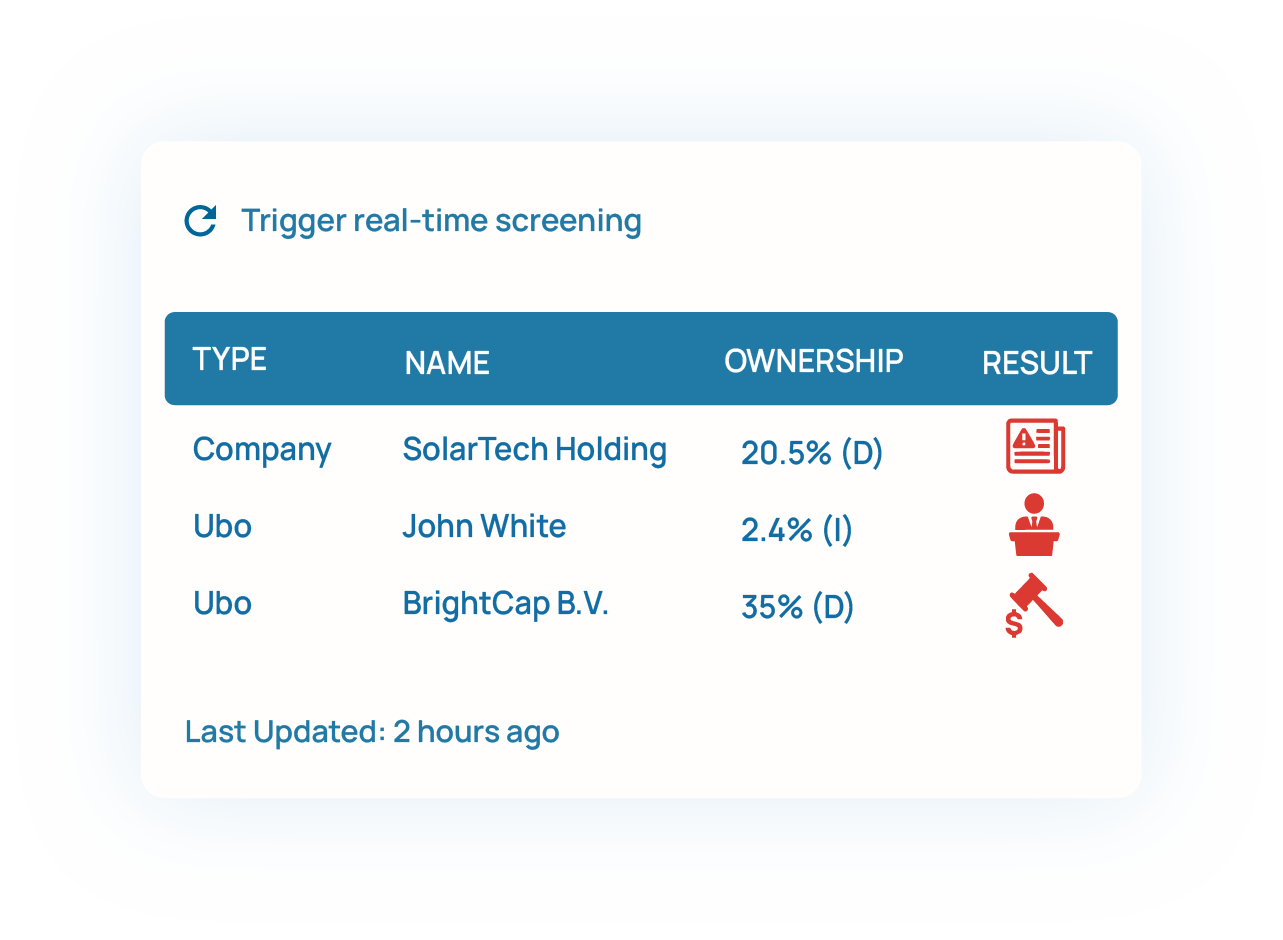

Due Diligence

Screening suppliers is not just about ticking a box. Business Radar combines sanctions, enforcement actions, and watchlist checks with portfolio-level monitoring, so you can verify suppliers at onboarding and keep oversight across thousands of partners.

Teams can upload supplier lists directly or connect the platform with ERP and procurement systems for automatic updates. Unlimited portfolio refreshes take minutes, which makes large-scale due diligence practical and efficient. Reports are audit-ready, giving you the evidence you need to demonstrate responsible sourcing to regulators, auditors, and customers.

Confident Supply Chains

By bringing together adverse media, due diligence, and a corporate full corporate overview in a single platform, Business Radar equips supply chain and manufacturing organizations with the intelligence they need to manage risk at scale. The result is stronger sourcing decisions, resilient supplier portfolios, and defensible compliance.